Custom Tins

Be Creative: Seven steps to perfect packaging

Form follows function. No matter how great your package looks, you will fail your customer if it doesn’t function as expected. Look to other products that get it “right”. Examples abound of good (and bad) packaging. Want to package your special gourmet spice blend? Venture outside of your product arena and make notes of what you like; look at CD covers for your favorite band or take a run down the skincare aisle of your local pharmacy. What stands out? Don’t limit your review to other packaging; ads, magazine design, even scrap booking how-to books will offer creative insight. You’ll find inspiration everywhere.

Size matters. Choose a tin size and style that makes the most sense for your product. Your budget and quantity requirements will also play a role in determining whether a standard, stock or custom tin is best.

To print or not to print. Considerations such as quantity, budget, brand image play a part in this decision. Labels are recommended for quantities less than 10,000 as a more economical option to printing directly on the tin. Allstate’s experienced sales team will advise you on your options and offer suggestions based on your specific needs.

Content. What goes on the label? Your product name and contact info is key (don’t forget your website!). Other considerations: safety information, ingredients, bar code, directions, and net weight. If you are marketing a food product, the FDA is the best resource for determining requirements. Make a list of everything you need to include and write copy. At this stage, content is king, don’t worry about the design.

Image. Think about the brand image you want to convey. Is your product and company upscale and elegant? Fun and Flirty? Cutting edge? Pure and simple? Or does your product beckon to nostalgic tradition? When you think of these descriptions, what pops into your mind? What typography do you envision? What color(s) speak to your image? Do you want a photograph of your product on the label?

Rough draft. Don’t worry if you aren’t “artistic”, just start sketching. Your sketches can be crude; squiggly lines for type, a triangle that represents your logo. The main thing at this stage is the layout: placement and size of your logo, product name, contact info...everything that needs to fit. Experiment with color combinations. If you’re more comfortable in front of a computer than you are with holding a colored pencil, by all means do your sketches electronically!

Design. At this point you may need to hire a graphic designer depending on your level of expertise. Use your sketches as a guide and you’re on your way to a professional and enticing package. Request templates from Allstate Can if you are planning a custom printed tin, or from your label printer if you’ve opted to use labels. Allstate Can’s pre-press department prefers receiving electronic files in Adobe Acrobat, Photoshop or Illustrator and our pre-press department is happy to provide guidance for setting up electronic files.

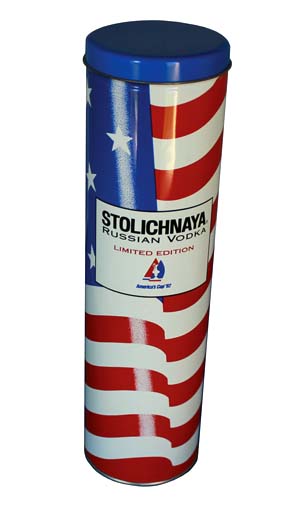

Think Tin®: Smart packaging. Big payoff

There are good reasons high end products are packaged in tins. Consumers make an emotional connection with packaging and tins offer a distinctive value that represents higher quality. Metal packaging yields greater returns than other options because products packaged in tins demand a higher price.

Allstate Can will work with you and your designers to create a package worthy of your brand. We have a team of professionals experienced in metal lithography and fabrication who will guide you every step of the way. Allstate has hundreds of options available from which to choose. The type of tin you choose is dictated by the product you want to put inside. One of Allstate’s sales team can provide expert advise and direction on the best solutions to meet your needs.

Put Allstate Can Corporation’s metal packaging to work for you to secure sales and get a higher return on your packaging investment. When you package your product in tins, the payoff is enormous:

- Amplified shelf appeal

- Enhanced value

- Heightened brand recognition

- Product prominence

- Made from recycled steel

- Reusable

- Recyclable

Q&A Tin Tips

Q: What is the difference between “custom”, “stock” and “standard” tins?

A: A can is considered “custom” if:

- It is a size for which tooling does not already exist

- Custom printing or embossing is required

- Modifications to existing tooling is necessary

- A height adjustment is needed on a standard or stock tin

Stock tins are normally available in our inventory and ready to ship. Standard tins are tin can styles that are not inventory items but rotate through our production schedule frequently.

Q: What are the benefits of selecting custom tins?

A: There are several benefits to ordering custom tins:

- Superior shelf appeal

- Convenience

- Four color process as well as special match PMS colors are available

- As volume increases, printing directly on the tins becomes more economical than labels

- All surfaces of the tin can be printed

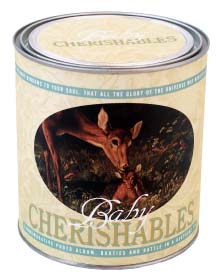

Q: What are the benefits of selecting stock or standard tins?

A: There are several benefits to ordering standard ot stock tins:

- Lower minimum purchase requirements for standard and stocked tins

- Economically test market new products before investing in custom printed tins

- Reduce your inventory overhead by using one tin size with interchangeable labels

- Shorter lead times

Q: How long does it take to get tins?

A: Lead time for standard or stock items is usually 1-4 weeks; custom items are generally 8-12 weeks from the time artwork is approved and depending upon the complexity of the project. Although we strive to maintain inventories of stock and standard items, demand may exceed supply. When this occurs, we will quote lead times. Lead times may extend by two-three weeks during peak demand, July-October and January-March.

Q: Is there a minimum order requirement for custom tins?

A: The general rule of thumb is 5,000-10,000 pieces for most round welded and lock-seam cans and 10,000-25,000 pieces for irregularly shaped tins. Another guideline holds that the smaller the tin, the larger the minimum order requirement.

Q: How are tins printed?

A: Most color printing is four-color process—the combination of cyan, magenta, yellow, and black to produce a virtually unlimited spectrum of color. Printing with special match (PMS), transparent and metallic inks is also available. Customers format their artwork to an Allstate supplied layout, our pre-press operation separates the art into its four colors from which printing plates will be ultimately made.

A proof is provided for approval, printing plates are made, then each color is laid via a printing press on flat sheets of metal. These flat pieces of metal are subsequently trimmed or “slit” and formed into the final tin shape.